Survey on the Methods of Nodular Cast Iron Production

Study submitted in the Symposium on Foundry Technology

Cairo December 1972

By

S.E. KHALIL— I.M MORSY —M.K HUSSEIN

The high consumption of Ingot Molds and the cracking of Cast Iron Pipes urge the Egyptian foundries to produce them from nodular cast iron. Ingot Molds made from this cast iron lasts 2:2.5 longer than that of gray cast iron (Ref. 1).

Nodular Cast Iron possesses excellent mechanical properties, its ductility is 5:15 times more than flaky graphite cast iron, and has good cast ability as well. Little attention has been directed to the production on Nodular Cast Iron in this country. And only three investigations (Ref. 2&4) are known to have been carried out till 1971 . h

The aim of this review is to show the Egyptian. Foundry-men the common known methods of magnesium treatment of cast iron and pointing out the most suitable of these methods to our work conditions. It is worth mentioning here that the nodular cast iron becomes more profitable where a continuous production is excessive. Therefore, a special line of production in foundries should be preserved for such job.

Since morrogh in 1947 (5) first announced the possibility of producing spheroidal graphite osst iron , the production of this type of cast iron was greatly increased. Now nodular cast iron is preferable for the production of many casting s such as crank shafts , rolls, ingot molds ,pipes… etc.

Many steel and non-ferrous casting can be replaced by nodular cast iron. The price per ton of this cast iron is 25-30% cheaper than of plain carbon steels. It is also 2:4 times cheaper than non-ferrous castings ,2-3 times cheaper than forged steels , and only 20-30% higher than that of grey cast iron.

The spheroidization of graphite takes place through modification of cast iron achieved through addition of Mg,Ce, or Ca using various addition techniques. From the afore-mentioned elements Mg is the most practically used one for spheroidization . The relatively low melting and boiling points of Mg and its high affinity towards oxygen and sulphur complicate the method of its addition. Besides, its high affinity to combine with sulphur leads to considerable consumption of the added element.

The necessary amount of residual Mg to achieve spheroidizaton of cupola cast iron lies in the range of 0.04-0.12% (Ref. 2).

Emperical formulae suggested by Stephen (Ref.6) and Girsheirch (Ref.7) can be used to determine the required amount of Mg as a function of the chemical analysis of cast iron and the thickness of the casting.

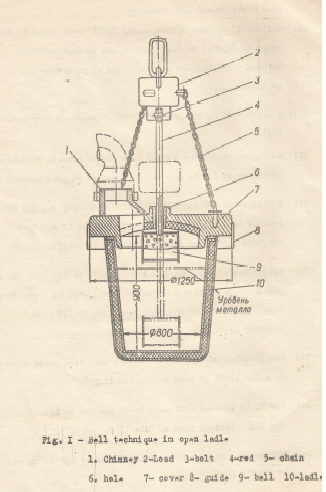

Methods of adding Magnesium: Pure Mg used in many foundries for the modification of heavy casting. When applied in open ladles and at atmospheric pressure, only 5:15% of the magnesium quantity added goes in the reaction, The rest either interacts with sulphur and oxygen or evaporates. Sometimes, The evaporization takes place intensively and is accompanied with the ejection of molten cast iron. This necessitates the use of special

chambers equipped with exhaust ventilation systems as shown in (Fig. I) which was quoted from (Reference 8).

.To simplify the process of Mg addition, different master alloys were used. These alloys should fulfill the following requirements:

- The components of alloy, other than Mg, should have high specific gravity in order to facilitate the sinking of the alloy into molten iron.

- Both melting and boiling points of alloy should be sufficiently high to ensure a calm reaction during addition.

- The alloy components must be as cheap as possible.

- The melting of the alloy should be feasible to medium size foundries.

- The recorded methods in the literature for the Mg additions, leading to successful formation of nodular cast iron are:

1.Mg metal is added in amount of 0.4:1% of the cast iron. If the addition is carried out under pressure, this amount can. If the addition is carried out under pressure, this mount can be decreased to 0.2:0.3, and the Mg uptake in the melt increases to 60% (Ref. 9). A strong reaction with low Mg, uptake is observed at atmospheric pressure. This type of addition is preferable for big castings.

2. The addition of Electron scrap (9% Al, 3% Zn, balance Mg in amount ranging from 0.5:1% loads to low uptake 5:7%, strong reaction, and sharp cooling of the cast iron.

3. The addition of Mg-Fe-Si alloy with Mg content more than 20% (specific gravity 3:3.4 g/cm³) leads to a low Mg uptake 5:10%, and strong reaction (Ref. 10)

4. The addition of Mg-Fe-Si with Mg-Content 5:10% (specific gravity 5-5.0 g/cm³) leads to a good Mg uptake and a calm reaction (Ref. 10). The alloy is added in amount form 1.5:3.5% of cast iron weight.

5.The addition of Mg-Ni (10-50% Mg) with specific gravity up to 7.4 g/cm3 and melting point of 1200°, leads to a Mg uptake ranging from 5 to 50%. The less mg content in alloy, the higher is the Mg uptake.

6. The addition of Mg-Ni-Fe-Si alloy (10-20% Mg,10-15% Ni, balance Si and Fe ) (Ref. 11) leads to a good

Mg recovery .

7. The addition of Mg -Ni-C (10-20%Mg , 10-80% Ni , 2-5% C, balance Fe) (Ref. 11) leads to a good recovery.

8. The addition of Mg – Cu (10-50% Mg) (Ref. 12) .

Mg-Ni-Cu (10-25%Mg, 20-30% Ni , 45-70% Cu),

Mg-Ni-Cu-Si (6-20%Mg, 13% Ni, 33% Cu, 26% si ) . (11,12)

Leads to variable recoveries depending on the Mg content.

9.The addition of Mg – Ca (Ref. 11&13), Mg-Si-Ca, Mg, Ca-Ni-Si-Fi (Ref. 12&14) also Mg-Si-Ca-Fe alloys (Re. 12) provides stable and reliable results. The reaction is calm and pyro effect is low. The ratios of Mg/Ca and Mg/Si are recommended to be 3.5-1.5 , and 1/3 -1/6 respectively.

10. The addition of Mg- A1(20-55%Mg) (Ref. 12) , and Mg-Si-Ni-A1(20-25%Mg, 30-40% Si, 20%Ni , 15% Al) (Ref. 11&12) leads to a good recovery . However, high A1 content in cast iron is not recommended.

11. The addition of Mg-Mn-Si (20%Mg, 13%Mn, 55%Si, balance Fe ) (Re. 12) , Mg-Ca-Si-A1-Mn-Fe (30% Mg , 20% Ca, 40% si , 2.5% A1, 0.5% Mn, and 7% Fe) (Ref. 12&15) has the advantage of the presence of Mn which acts as desulphurizer . It can substitute Mg in this respect to a great extent.

12. The addition of Mg-Li alloy (up to 90% Li) (Ref. 16) provides a calm reaction with Mg uptake 5-10%

13. The addition of Mg-Zn (25-50%Mg) alloy (Ref. 17), Mg-Zn-Cu (50%Mg,15%Zn) leads to a low recovery.

14. The addition of Mg –Sb (20%Mg) alloy (Ref. 16&18) leads to a small recovery . The presence of more than 0.026% Sb in cast iron results in obtaining flaky graphite.

15. The addition of Mg-Ca-Ba-Sr-Si-Cu alloy (2-20%Mg , 2-15%Ca) leads to a good recovery (Ref. 18) and satisfactory results are obtained.

16. The addition of Mg- Ce (55-73% Mg) (Ref. 19&20) and Mg with mish- metal (Ref. 21) ensures stable results as the effect of Mg and Ce as spheroidizing agents are strengthened. The disadvantage of adding each element separately, i.e. vigorous reaction for the former and the limited use of the latter for hyper-eutectic cast iron are eliminated. The nodular cast iron is formed at 0.005% Mg and 0.001% Ce.

17. The magnesium nitride Mg3 N2 (Ref. 22) can be added in amounts of 1% . The nitride decomposes at 115C , resulting in calm reaction.

18. Mixture of 10% Mg shaving and 90% crushed Fe Si leads to good recovery and calm reaction.

19. Mixture of calcium cyanamide and Mg-Ni & Cu-Si alloy in the ratio of (0.5:1) to (6:1) (Ref. 23) leads to good results. Calcium desulpharizes cast iron and so partially substitutes Mg.

20. A mixture of Mg and MgO (3-10% Mg) provides a calm reaction (Ref. 24).

21. A mixture of crushed Mg and Zr added in amounts such as to obtain up to 0.1 Mg and 0.3 Zr , results in good recovery (Ref. 25)

22. A mixture of 34% Mg, 33% cast iron shavings, and 33% crushed Ferrosilicon 75 (Ref. 26) is pressed under 40 tons and is added as briquettes of 40 mm diameter and 120 mm height.

23. Briquettes of Mg, FeSi-75, and MgO (Ref. 27) or Mg, FeSi-75, and graphite provide calm reaction and high Mg recoveries. Also, briquettes of Mg, FeSi, and Ca (Ref. 3&28) lead to a recovery up to 80%

24. Blowing of Mg power in molten cast iron using nitrogen or argon leads to good recoveries (Ref. 2&29).

25. The Mg in gaseous form with inert gas can be introduced in the ladle through special tube (Ref. 30).

26. The melting of cast iron under a layer of Magnesium oxide or dolomite at 1700°C (Ref. 19).

- Production Techniques:

There are many techniques for the production of spheroidal graphite cast iron, among which are the following:-

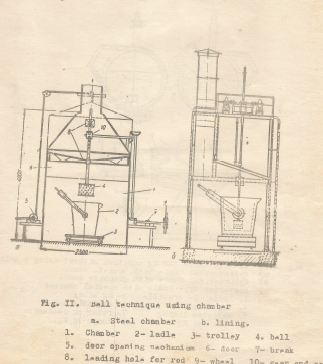

1. The introduction of Mg or its alloys by a bell in ladles: These ladles may be open Fig. I (Ref. 31) or existing in a chamber Fig. II (Ref. 8).

2. Modification in cylindrical tilting ladle with bucket and graphite cone (Ref.32-34),Fig. III. In this case, there is no need for bells and their accessories.

3. Modification under pressure Fig. IV (Ref. 35)

4. Modification in cupola receiver Fig. V (Ref. 36)

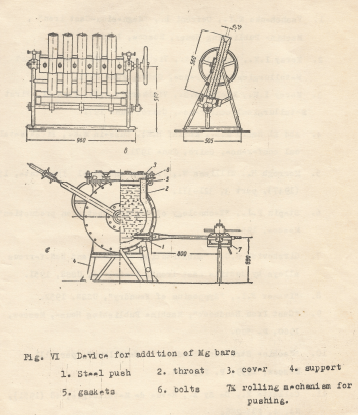

5. Modification by means of Mg bars Fig. VI (Ref. 37)

6. Modification by injection of Mg powder (Ref. 2,38,39)

Recommendation for production of nodular cast iron in Egypt.

In our local conditions, attention may be directed to Fe-Si-Mg -Cu alloy (10% Mg – 45% Fe-35% Si-10%Cu) to be added by the bell technique. Here, the perforated bell is introduced in a cylindrical ladle specially designed with a cover and provided with ventilation system. This choice has been made because of the following reasons:

i. The low cost of alloy components.

ii. The availability of alloy components, except Mg, in the local market.

iii. The simplicity of addition technique.

iv. The feasibility of the production of this alloy in our foundries

v. The advantage of the presence of Si in the alloy which promotes graphitization.

Trials must be carried out to apply the technique of addition in the cupola receiver .

Moreover, the unit for magnesium powder injection at El-Nasr Casting Co. can be used after slight modification to avoid the blocking of the lance.

- References:

1. Vashchenko K.I., Cofroni L., “Magnesium-Cast iron”, Machine Publishing House, Moscow, 1960,

2. Morsy I.M. Khalil S.E., Vishkariev A.F., First Metallurgical conference, Cairo, June 1971.

3. Morsy I.M, Khalil S.E., Vishkariev A.F., First Metallurgical conference, Cairo, June1971.

4. Abd El Hamid M.B., Khalaf H.M, Hussein M.K., First Metallurgical conference, Cairo, June 1971.

5. Morrogh H., Williams W.J. , Iron and Steel Institute, 155 (1947), part 3, 321-371.

6. Stepin P.J., “Technology of ductile cast iron production”, Moscow, 1956.

7. Girshovich N.G., “Substitution of steal and Non.ferrous alleys by ductil cast iron”, Leningrad, USSR, 1951

8. “Ivanov F.I., “Symposium of Foundry”, USSR, 1952.

9. “Cast Iron Handbook”, Machine Publishing House, Moscow, 1960, P. 590.

10. “Machine Structure Handbook- Cast Iron”, part 111, Moscow, 1959, P. 253-294.

11. Collette R., De Sy A., Revue de Metallurgie, 48 (1951), No. 4, 283-288.

12. Zakharov V.A., “New in Foundry”, Section 2, Gorky, USSR, 1957, p.78-79.

13. De Sy A., Collette, De Vidts, Fonderie Belge 2 (1951) 34-42; Gisserei, 39 (1952), N.4, 83-84.

14. Dantzenberg W., Metalhutte Mark A-G, English Patent 721738, 12.0.1.55.

15. Kusakawa R., Japan Pat. 2207, 10.05.53.

16. Smolley O., US patent 2625473, 13.01.53.

17. Venerholm G., Bogart H., Melmoth R., “Foundry Trade Journal, 88, March, (1950), 247-256.

18. Vanadium Corporation of America, E. pat., 692848, 17.06.53.

19. Morrogh H., “BGIRA”, Journal of Research and Development (11952), 251-292.

20. Livingston J.A., Pat. Franc. 1035055, 14.08.53.

21. Ford Motor Co Ltd., E.P. 735858, 28, 09.1951.

22. Yoda R., J. “Japan Institute of Metals”, 18 (1954), 250-255.

23. Mitsche R., Modl E., Australian Pat. 175592, 27.07.53.

24. Busby A.D., US pat. 2663635, 22.12.53.

25. Offenhauer Ch.M., “Electro-Metallurgical Co. of Canada Ltd.”, Canadian Pat. 500910, 23.04. 54.

26. Vasilenko A.V., Ductile Cast Iron, USSR, 1951, p.99-103.

27. Kecyoe Tunbae (China), 1953, No. 12, 69-71.

28. Kusakawa T., Wasseda Univ., Rept. Cast. Res. Lab., (1954) No. 5, 7-10.

29. Bull, Brit. Cast Iron Res. Assoc., 12 (1954), No. 5, 254.

30. Marincek B., Giesserei, 37 (1950), No. 23 523-524.

31. Shapranov I.A., New in theory and practice of casting, Leningrad, USSR, (1956), p. 134-152.

32. Wittmoser A., Giesserei, 41 (1954), No. 5, 105-108.

33 Patterson W., Giesserei, (1953), No.11, 549-582.

34. Ryabukhov G.I., Li taynoe proizvodstva, USSR, (1956), Ne. 3. p. 26.

35. Van Tsun-Min, “Symposium of nodular cast iron”, Polytechnical Inst., Pekin (China), (1958).

36. Petrov I.P., Liteynoe proizvodstva, (1958), No. 5, p.12-13

37. Piaskcwski J., Jankowski A., “Zeliwo Sferoidalne” PWT, Warszawa, (1957).

38. Jankowski A., “Przeglad Odlewnictwa”, (1956), No. 5, 131-139.

39. Pozdnyshav V.M., Dissertation, Moscow, (1958).