MAINTENANCE MANAGEMENT

A Study Discussed with Bin-Laden Engineers

Jeddah 1992

Main Topics

- Preventive Maintenance

- Scheduled Inspections

- Maintenance Organization

- Diesel Engine Care

- Maintenance requirements of the following Systems

- Air Intake and Exhaust

- Lubrication

- Fuel

- Cooling

PREVENTIVE MAINTENANCE “PM”

PM DEFINITION

PM IS A CAREFULLY PLANNED SYSTEMATIC PROGRAM OF INSPECTING, TESTING, ADJUSTING, AND SERVICING. IT INVOLVES KEEPING ACCURATE RECORDS, SO PERFORMANCE AND OPERATING COSTS CAN BE EVALUATED

PM CONCEPTS

- PM KEEPS LITTLE PROBLEMS FROM BECOMING BIG ONES

- PM AVOIDS SUDDEN UNEXPECTED STOPPAGE THAT LEADS TO DOWNTIME

- PM EXPECTS MAJOR FAILURES BEFORE IT HAPPENS “NINETY PERCENT OF ALL FAILURES GIVES WARNING SIGNS BEFORE THEY OCCUR”

- PM PROVIDES A BETTER RUNNING, SAFER, AND MORE PRODUCTIVE EQUIPMENT

- PM HELPS IN FORECASTING MAINTENANCE COSTS MORE ACCURATELY

- ALL PM OPERATIONS ARE DONE WHILE THE UNIT IS STILL IN SERVICE WITH THE MAIN TARGET OF KEEPING IT ON DUTY WITH THE SAME PERFORMANCE

PM PRINCIPLES

-

THE PRINCIPLE OF “PREVENTION”,e. The Early Control Of Events, Is Better Than Leaving Them To Happen, And Look After For A Cure.

The principle of prevention extends to human health and safety to quality control and virtually to every field of human endeavor.

The concept of prevention is the fundamental philosophy of regulating events rather than being regulated by them.

-

THE PRINCIPLE OF THE “SCIENTIFIC WAY” OF PREVENTION.

Prevention does not just happen by itself it require scientific knowledge derived from reproducible experiments. This introduces the whole scheme of collection and analysis of Data.

The application of the scientific method of preventing troubles and problems from happening has two folds:

-

Technical fold, and

-

Statistical fold.

PREVENTION needs to be implemented by:

-

Applying manufacturer recommendations

-

Applying an accurate recording system which should includes: data collection, record keeping, and analyzing results.

-

The principle of “”Staff Assistance”

This is an organizational concept. We have to realize that any extensive effort for collection and analysis of “DATA” requires time and skills not possessed only by supervisors. This effort must be supplied by some skilled personnel who should apply the preventive maintenance as scheduled.

- The Principal of “Staff Cooperation”

All on-site personnel should perform as one team each in his activity, under the umbrella of P.M. to achieve downtime prevention as their common goal”

use of the forgoing three principals will achieve Prevention, but they cannot be used separately, they must work together, they must be COORDINATED.

PM ATTITUDE

The aimed at objective of applying a PM program is to prevent unscheduled downtime form happening.

- Preventive Maintenance can forecast major troubles before its occurrence and point out in advance sources of expected failure.

- Preventive Maintenance is a sort of control on the machine or equipment to keep it running economically and profitably by performing regular periodic comparative checks, while the machine is still running and productive, (note that PM is done out of production time).

Most of business men call PM “Productive Maintenance” as they pay for it by their own initiative material, tools and men while their machines or equipment are still productive, to gain PM benefits by avoiding the unexpected cost of downtime.

Causes of “Unscheduled” Downtime:

Causes of down-time can be resolved into two basic components

-

That due to the operation of forces working at random, it is termed as insignificant or “unassignable” causes (i.e. by chance).

-

That due to the operation of forces working consistently in particular direction (i.e. Assignable Causes).

The purely random causes represented by the first, are termed “non-significant”, it is the one that merits no investigations. It arises from what is known as a constant system of chance causes and no amount of engineering effort can have the slightest influence upon such system.

The non-random causes of stoppage comprising the second are termed

“Significant”, for’ they signify the ‘presence of an assignable cause of variation as operation of that (e.g. Machine member) is allowed to continue unchecked will sooner or later give rise to unscheduled down time.

A continuous process, yielding production (by any measure) is called STABLE if its causes of stoppage are still lying within the non- assignable causes limits. It is called unstable if it goes through the assignable cause’s limits, a matter of which should not happen if your preventive maintenance program is well scheduled and well controlled.

Some Examples of assignable causes of stoppage:

- Errors in operation (misreading of instructions, carelessness of machine handling, etc.)

- Faulty attachment or implement.

- Difficulties imposed by design (e.g. engineering, limits are too narrow)

- Faulty material application.

- Inadequate machine maintenance.

Preventive Maintenance Steps:

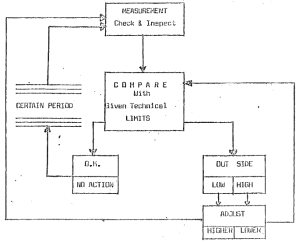

The following flow chart gives the general Preventive Maintenance steps which can be applied in most cases:

Maintenance Organization

-

Preventive Maintenance SUBDIVISIONS

Any preventive maintenance system should incorporate the following 5 preventatives:

-

Preventive Maintenance Records Section

Its function is to prepare and insure on demand records and file all service reports, (inspection record cards) and associated actions taken.

Preparation includes analysis of measurements, recordings on record cards, ready for issue when required and available for instant use.

-

First Off Section

They are inspectors, belonging to P.M. department. Their function is to approve or reject and make comments on the machine first received “NEW”, stay until production goes on a sound basis, then place record cards in the appropriate container or display board. This job will then be of an advisory capacity in the event of trouble or develop as work proceeds.

-

Patrol Inspectors “Lube Man, etc.”

Their function is to visit the machine each in his section which are in production at regular intervals indicated on the record cards and maintain control on the key points as established by the first-off inspector who originally approved the machine set up.

-

Foremen

As the fundamental object of preventive maintenance is to stabilise all operations and keep unscheduled down-time at a minimum. Foreman can also play an effective part in achieving these objectives by interest and continous stay in the operation field, cooperating with production people.

-

Operators Roll

Preventive maintenance is a matter of interest just as vital to operators as to any other individual or section in the organization. If the machine is set correctly, gauges are provided, checking time is allowed for and clear instructions have been given, the value of the preventive maintenance program is very large in the hands of the operators and should be a matter of interest to them no less than bosses.

-

Preventive Maintenance Economics

As we have said in the beginning and defined preventive maintenance as a concept of preventing unscheduled down time from happening, this is a relative matter, as zero percent stoppage time that cannot be achieved In reality. We as humans always speak about matters relatively, leaving absolute subjects only for Allah.

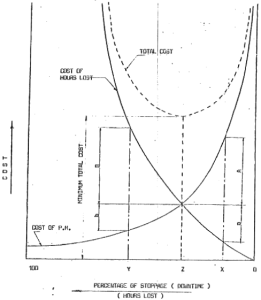

We should be satisfied about certain logical percent of down time, but “Logical” is not in our dictionary, as stated in the second principle of preventive maintenance, we should use the “Scientific Method of Prevention. This certain percent of down time can be calculated from the economical side. Looking to the following diagram we see two curves. The first represents the cost of preventive maintenance program which is increasing as the percent of stoppage hour decreases. The second is the cost of working hours lost due to stoppage, it increases as stoppage hours increases. Summing up the two curves we get the total cost curve which has one minimum peak represents the minimum total cost which will be at Z% of stoppage hours with respect to total working hours.

When using the first two curves alone neglecting the total cost curve, you will get wrong results as you will see through the coming two examples:

First example: is an ideal contractor who wants to work at a less expected stoppage hours than Z, so he shifted it to point X thinking that he is saving the amount a from the costs of lost hours. In fact he is really losing the amount A from his P.M. program – “A” is bigger than “a”.

Second example: is a contractor who wants to save the amount b from the cost of his P.M. program, but in fact he is really losing the amount of B through the cost of more stoppage hours, B is bigger than b.

Returning back to our early talks again, we have said “P.M. is a sort of control on the machine, by performing regular and periodic comparative checks……”. PERIODIC; how, each shift or each year? It is not a matter of guessing. Once again the principle of scientific method for prevention plays its roll. Here it has two folds: 1. Technical. 2. Economical.

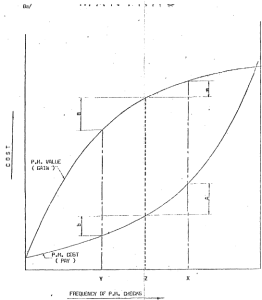

For the economical side let us look over the coming diagram. It has two terms:

- The first represents the cost of P.M. (which you pay ), against the frequency of P.M. checks, which starts with small slope and after that the costs of P.M. increases rapidly as the frequency of checks come too close.

- The second curve represents the value of P.M. (which you gain ), against the frequency of P.M. checks, which starts with big slope, and after that the value of your P.M. program increases very slowly as the frequency of checks come too close.

It is evident that the difference between the two curves is a profit, taking the point of the maximum difference which is the point of maximum profit at Z frequency of preventive maintenance checks.

Let us look for more P.M. value by increasing the amount of checks per the i.e. moving point Z to point X certainly we will gain the amount a. But at the same time we will lose the amount A on the P.M. cost curve. Note that A is bigger than a.

Once again, let us look forward for more saving by decreasing P.M. costs, the value b and decreasing the number of periodic checks to point Y. Notice that we will lose the amount B from the value of our P.M. program and B is bigger than b.

The point Z was already calculated for you in all lubrication and maintenance guides you have for all your CAT machines. In some special cases you may do it for yourself.

General Mistakes in Applying PM Program:

The following points are the common mistakes which you should avoid in establishing and controlling your preventing maintenance program, especially when starting in an already established organization:

1. Mistakes in Value

1. Confusion between preventive maintenance and the major repairs.

2. Unwilling to pay for progress.

3. Resistance to change.

4. Desire to avoid trouble.

5. Starting one policy and meaning another.

6. Compromise of basic principles.

7.”I believe in the principle but …….”

8.Lack of agreement or inadequate teamwork.

9. Allowing a daily routine to interfere with major objectives.

2. Mistakes in Knowledge

- Believing that preventive maintenance means less production.

- Evaluating cost on a short term basis.

- Lack of vision.

- Emphasizing jobs more than processes.

- Choosing between two alternatives with real knowledge of only one.

- Placing blame of stoppage on the operators.

- Lack of understanding habits and culture.

- Lack of correct training.

3. Mistakes on Judgment.

- Fear of making a mistake.

- Taking causes for granted rather then checking them out.

- Overlooking the little things in favour of miracle solutions.

- Distributions of responsibility.

- Insufficient pressure from above.

PREVENTIVE MAINTENANCE EXAMPLES

Early in our talks, we spoke about those people who call preventive maintenance, productive maintenance. The following examples will show how ineffective or poor preventive maintenance can turn to a big loss :

- Changing bucket paddle plates in P.M. or changing the whole bottom in repair.

- Changing a broken window glass in P.M. or making an engine overhaul due to dust and dirt inters in major repair.

- Changing a worn out oil seal in P.M. or installing a new shaft, bushing assemblies and seals after in major repair.

- Changing the sproket for a broken tooth or let it work now.

- Buy a new radiator cap or close it now with a reg.

- Cleaning crankcase guard from mud.

- Buy a new radiator guard or let it go on working until you are bound to change the radiator core.

Diesel Engine Care

Maintenance requirements of the following selected Systems

-

Air Intake and Exhaust System

- Cover exhaust stack when equipment is parked or moved by rail or truck.

- If stack is removed, cover exhaust opening.

- On excavators, turn exhaust stack opening to right rear of machine to 4 o’clock position.

- Remove pieces of failed turbochargers from air system; replace inner safety filter in dual filter air cleaner or single filter in two stage air cleaner.

- Inspect filters often look for:

- Excess soot (sometimes means exhaust leak exists).

- Bad gaskets and seals.

- Excess dirt.

- Filters usually can be reused 3 or 4 times–keep track of cleaning and inspection dates. Don’t clean too soon.

- Replace filter only when air cleaner indicator is locked in warning position when red piston stays up with engine off.

-

Fuel System

- Keep dirt and water out of the system.

- Keep filters clean; replace on time. Clean filter housing and gasket, and gasket joints before changing.

- Drain contaminants out of fuel tanks every 125 hours.

- Drain contaminants out of fuel filter housings every 50 hours.

- Use common sense – clean screen if removed; wipe off hose nozzle, fuel tank cap stem before refueling; wipe off parts to be repaired, and use plugs and covers to seal dis- assembled pumps, valves and lines.

- When engine runs rough, check other parts of engine before changing nozzles and pumps.

- Buy clean fuel. Make certain supplier guarantees fuel to contain no more than 0.1% sediment and water.

- Keep fuel clean – have supplier refuel machines if possible. Otherwise clean and drain storage tanks periodically.

- Fill fuel tanks when machines stop work – not at the beginning of the work shift.

-

Lubrication System

- Remove drain plug from filter base before removing filter element.

- Remove and clean breathers every 250 hours.

- Always cut open and inspect discarded filters. Learn to identify metal debris.

- Maintain records for systematic lubrication.

-

Cooling System

- Keep radiator clean

- Clean and check radiator caps and pressure relief valves.

- If your machine is losing coolant but systems pressure is normal and no overheating problem or external leak exists…

- First perform the following test: push a rubber tube — over end of radiator overflow tube and put free end of tube into water filled jar inverted in bucket of water. If engine running at high idle pushes at least one pint of gas into bottle in 30 seconds, internal leak may be present.

- Check for a leak into engine through a small crack in cylinder head.

- Check for leaking pre-combustion chamber seal, damaged gaskets or a loose cylinder head.

- Check for damaged core plug or leaking heat exchanger.

These tips do not make a complete maintenance program. For information on regular maintenance procedures, see the appropriate publications (Operation and Maintenance Instructions, Operator’s Guide, Maintenance and Lubrication Guides) for your machine or ask your dealer.

;

- Air Intake and Exhaust System

- Cover exhaust stack when equipment is parked or moved by rail or truck.

- If stack is removed, cover exhaust opening.

- On excavators, turn exhaust stack opening to right rear of machine to 4 o’clock position.

- Remove pieces of failed turbochargers from air system; replace inner safety filter in dual filter air cleaner or single filter in two stage air cleaner.

- Inspect filters often look for:

- Excess soot (sometimes means exhaust leak exists).

- Bad gaskets and seals.

- Excess dirt.

- Filters usually can be reused 3 or 4 times–keep track of cleaning and inspection dates. Don’t clean too soon.

- Replace filter only when air cleaner indicator is locked in warning position when red piston stays up with engine off.

- Fuel System

- Keep dirt and water out of the system.

- Keep filters clean; replace on time. Clean filter housing and gasket, and gasket joints before changing.

- Drain contaminants out of fuel tanks every 125 hours.

- Drain contaminants out of fuel filter housings every 50 hours.

- Use common sense – clean screen if removed; wipe off hose nozzle, fuel tank cap stem before refueling; wipe off parts to be repaired, and use plugs and covers to seal dis- assembled pumps, valves and lines.

- When engine runs rough, check other parts of engine before changing nozzles and pumps.

- Buy clean fuel. Make certain supplier guarantees fuel to contain no more than 0.1% sediment and water.

- Keep fuel clean – have supplier refuel machines if possible. Otherwise clean and drain storage tanks periodically.

- Fill fuel tanks when machines stop work – not at the beginning of the work shift.

- Lubrication System

- Remove drain plug from filter base before removing filter element.

- Remove and clean breathers every 250 hours.

- Always cut open and inspect discarded filters. Learn to identify metal debris.

- Maintain records for systematic lubrication.

- Cooling System

- Keep radiator clean

- Clean and check radiator caps and pressure relief valves.

- If your machine is losing coolant but systems pressure is normal and no overheating problem or external leak exists…

- First perform the following test: push a rubber tube — over end of radiator overflow tube and put free end of tube into water filled jar inverted in bucket of water. If engine running at high idle pushes at least one pint of gas into bottle in 30 seconds, internal leak may be present.

- Check for a leak into engine through a small crack in cylinder head.

- Check for leaking pre-combustion chamber seal, damaged gaskets or a loose cylinder head.

- Check for damaged core plug or leaking heat exchanger.

These tips do not make a complete maintenance program. For information on regular maintenance procedures, see the appropriate publications (Operation and Maintenance Instructions, Operator’s Guide, Maintenance and Lubrication Guides) for your machine or ask your dealer.