About Quality

An article published in T. S. S. March 1971 written by Morsy I. M.

N.B:

The word quality is one which is not always clearly understood since it implies a relative degree of excellence, an article can be described as being of good quality or of reasonable quality depending upon the scale of judgment adopted by the person making the assessment.

Introduction:

The main target of introducing a quality control system in production processes, is to minimize the defective products which leads to no waste in labor time, labor effort, and material.

This gives a general constancy and improvement. of the product quality at reduced costs. The quality of the product while being manufactured can be indicated from process inspection data, plotted on quality control charts (figure 1) ; which gives in real times response, to provide on lines control,

Quality Measures:

In practice, however, it is either impossible, or impracticable, or not economical to control all the conditions precisely, Raw materials is not uniform, machines and tool wear, and effect of human factor are all sources of variations. This stress the fact that no repetitive manufacturing process can or will produce articles that are exactly alike.

Variability of the production process can be resolved into two components

(1) That due to operation of forces working at random I.e, chance causes It is termed non-significant, or non-assignable and arises from what is known as a constant, system of change causes and no amount of engineering effort can have the slightest influence.

(2) That due to operation of forces working in some particular direction i.e. significant, or assignable causes. It is controllable causes which gives real time response to provide on line control.

Differentiating between the two reasons is a simple statistical problem, while knowing the source of assignable causes and adjusting it. Is an engineering and technical problem.

Quality Measures:

Quality is any characteristic of the product of a factory, of intermediate product, or of the raw material that is of interest.

The specification and measurement of the quality of individual things is entirely a technical and engineering problem. Quality may be something which is required to be neither than nor less than a certain value, or it may be described qualitatively or in terms of numerical measure (quantitatively).

Quality simply, means customer satisfaction at acceptable price. By this concept standard quality levels is established

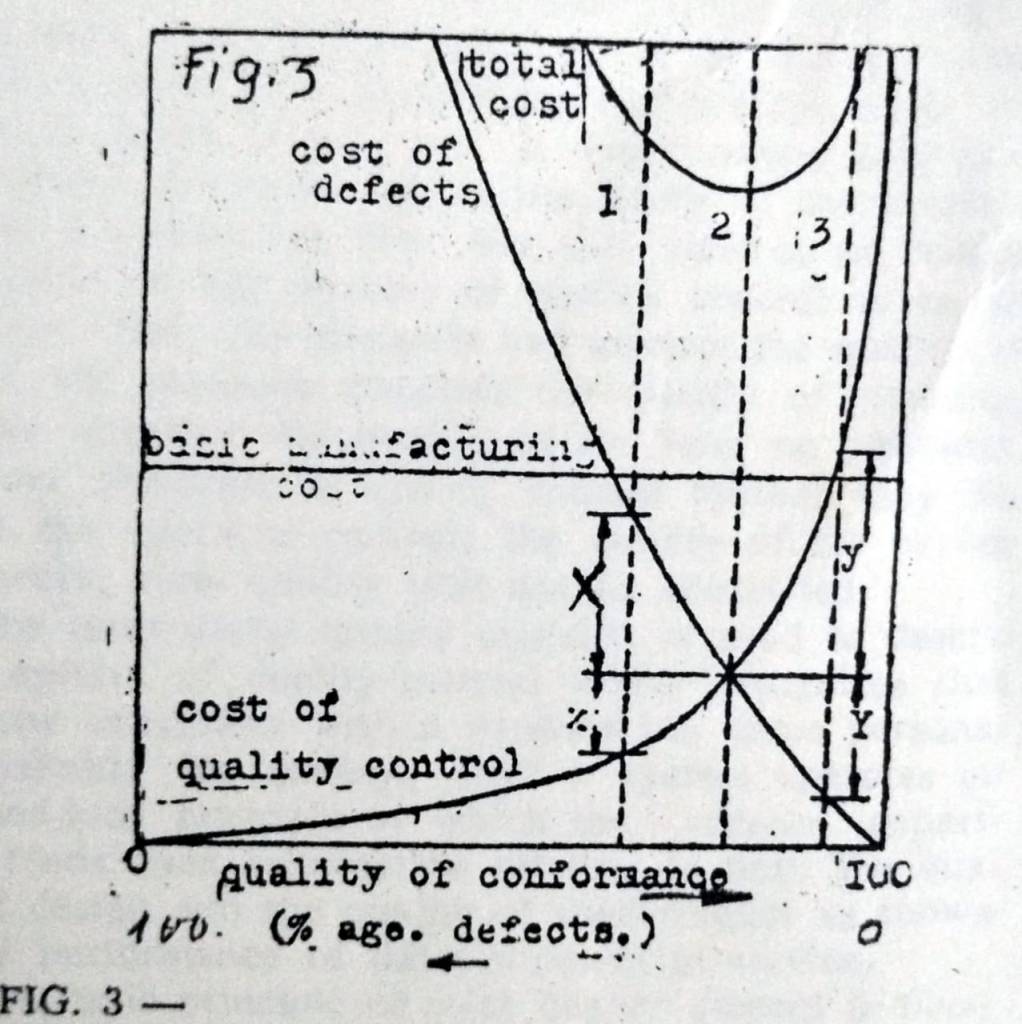

Figure 2: Curves indicating the economies of quality of design. The most economical design is the vertical line number 2. If the quality is reduced to line I, the cost of quality falls by (a) but the value of quality falls by larger amount A. If quality is raised to 3, the value of quality rises by 8 but the cost of quality rises by a larger amount b.)

Figure 3: Curves indicating the economics of qua;ity of conformance. The most economical degree of conformance is 2. If the quality of conformance is reduced to 1, the cost of defects rises by X but the cost of quality falls by a small amount If the quality is raised to 3, the cost of defects falls by Y but the cost of quality rises a larger amount. Y)

Termed significants, and when operation, if allowed to continue unchecked, will sooner or later give rise to defective product.

Quality Control, and inspection.

The operation of comparing a product with accept-ed specifications, and/or other recognized standard, is known as einspections. It is performed on the pro duct after it has been completly processed. Inspection is a screening operation and serves only to separate products that conform to specifications from those which do not conform.

Inspection does not add to the value of the pro duct or improve its quality. It very often interferes with production schedules established. Rejections at Inspection operation means scrap or rework, which add the cost of the product.

As a result of this inspection screening operation customer may guarantee a product of maximum quality, at the expense of economy. The problem is, how to guarantee a product of high quality and not nave, the loss of high percentage of rejections. Quality con trol attempts to solve this problem; by setting up conditions so that defective products will not result from the processing operation.

By establishing a definite level of quality, and charting process inspection data on quality control charts, which give information about the quality of the product while being manufactured, and forecast what will happen in the future to the processes, qua lity, and tool deterioration. So, it enable corrective actions to be taken as soon as things being to go wrong Figure 1, shows the main features of a quality control chart

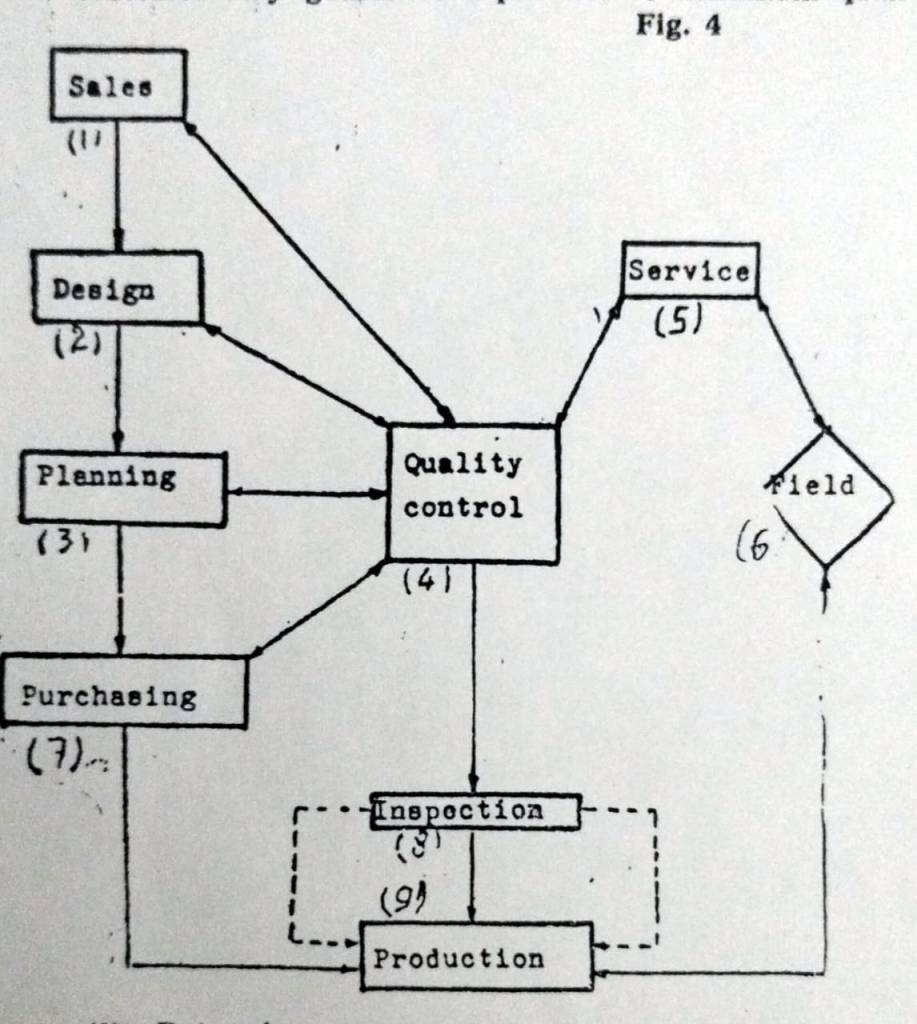

(1) Sales and Marketing: Determine customers’ quality requirements

(2) DESIGN for required quality and reliability

(3) Plan method of production to required quality

(4) Control to Provide services to all departments.

(5) Feedback of information to factory.

(6) FIELD

Achievement of control requires four related principles:

1. The principle of prevention.

2. The principle of scientific method of prevention,

3. The principle of Staffs assistance.

4. The principle of coordination.

(7) Purchasing: row material of required quality.

(8) INSPECTION

(9) Produce to required quality, Produce of required quality.

Fig. 4 Block diagram illustrating the concept of total quality control

cost of quality rises by a larger,

Economic of Quality:

In discussing the quality of an article, care must be taken to distinguish between the quality of the on zinal design and the quality as measured by the closeness of compliance of all the resulting manufactured articles with the the design. The former is know as squality of designs and the later as squality of conform .

In considering the quality of design of an article, the problem is to stric a balance between the additlonal cost of a higher quality of design and the increase ed value of the resulting product. For example, if gold plating a part does not add significantly to the life. reliability in service, or appearance of an article, the the cost of the better quality design is not justified because the value would not be increased. Similarly with quality of conformance. If it were possible to achieve 100% conformance with the design at every stage in production, the cost of scrap articles and subsequent rectification costs would fall to nil but the cost of production would rise so high as to render the article unsaleable

These problems are illustrated in dia-gramatic form in figs. 2 and 3, which show that there is an optimum economic quality level for both design and production. The scales adopted will differ for each article produced but the general shape of the curves will always be the same

Total Quality Control

on if effective control of quality of mass produced items is to be achieved, then each person concerned the design, manufacture and sale of an article must accept a personal responsibility for quality when the article is in his or her care, it was formerly held that the control of quality lay in the hands of the inspect production line, but this view is no longer acceptable if any system of quality control is to be effective. Only the designer can control the quality of design, the planning engineer the quality of planning. and the operator the quality of the item he produces. However elaborate a quality control system may be, unless the operator controls the quality of his or her own work, then quality will not be controlled.

The term total quality control is used to describe a system of quality control which recognise that everyone concerned with a product has some personal responsibility for quality. Such a system operates on a closed-loop principle in which the service department feeds back information relating to both the quality of design and the quality of conformance as shown by the performance of the equipment in service.

The basic principle of total quality control is illustrated in fig 4, which shows the flow of information on quality to and from the quality control department The inspection department has a direct feedback path so that adjustments can be made to tools or processes by the production department to correct any undesirable trends which are detected